Step into the realm of Karman vortex air flow sensors, where the dance of vortices orchestrates a symphony of airflow measurement. These ingenious devices harness the power of fluid dynamics to provide invaluable insights into the intricate world of air movement.

Karman vortex air flow sensors have carved a niche for themselves in diverse industries, from automotive engineering to environmental monitoring. Their ability to accurately measure air velocity and flow rate makes them indispensable tools in applications demanding precision and reliability.

Overview of Karman Vortex Air Flow Sensor

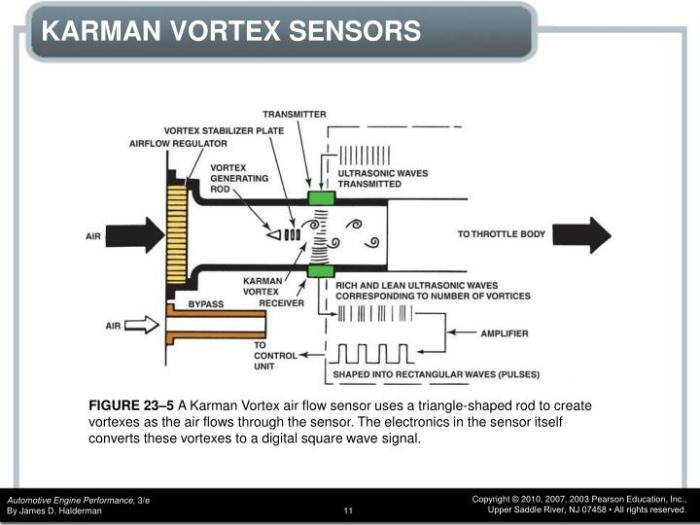

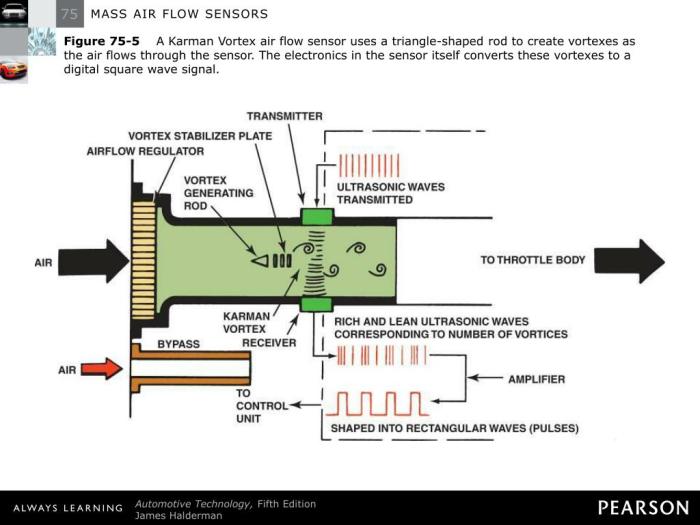

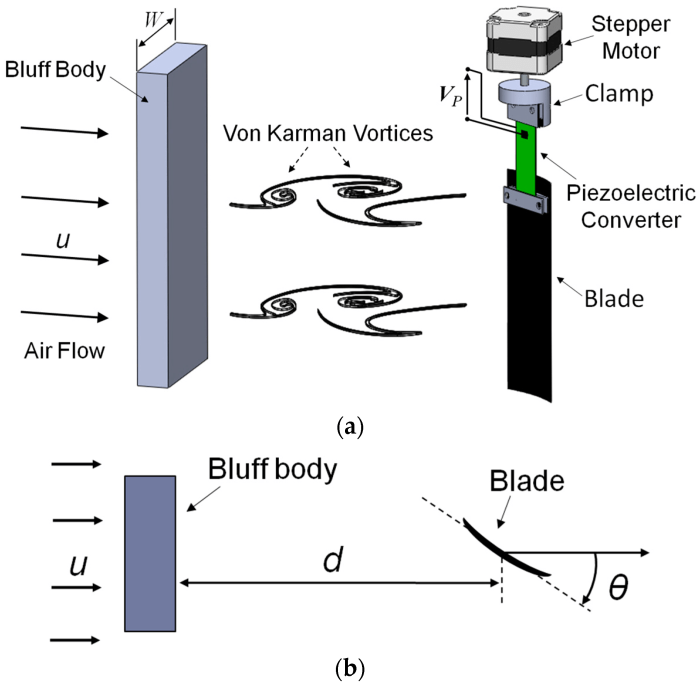

Karman vortex air flow sensors are a type of flow sensor that utilizes the principle of vortex shedding to measure the flow rate of a fluid. These sensors consist of a bluff body, typically a cylinder or a prism, placed in the path of the fluid flow.

As the fluid flows past the bluff body, it creates a series of alternating vortices, known as Karman vortices, which are shed downstream of the body.

Principles of Operation

The formation of Karman vortices is a result of the interaction between the fluid flow and the bluff body. As the fluid flows around the body, it creates a boundary layer that separates from the surface of the body at a certain point.

The separated boundary layer then rolls up into a vortex, which is shed downstream. The frequency of vortex shedding is directly proportional to the flow velocity, and this relationship can be used to measure the flow rate.

Applications of Karman Vortex Air Flow Sensors

Karman vortex air flow sensors find applications in various industries and sectors, owing to their accuracy, reliability, and cost-effectiveness. Here are some common examples:

– Automotive Industry:These sensors are used in engine management systems to measure airflow rates, aiding in fuel injection and emission control. – HVAC Systems:Karman vortex sensors are employed in heating, ventilation, and air conditioning systems to monitor airflow rates and adjust fan speeds accordingly, ensuring optimal indoor air quality and energy efficiency.

– Industrial Processes:In manufacturing and industrial settings, these sensors measure gas flow rates in pipelines, ducts, and chimneys, enabling precise control of processes and reducing emissions. – Environmental Monitoring:Karman vortex sensors are used in environmental monitoring systems to measure wind speed and direction, providing valuable data for weather forecasting, pollution control, and renewable energy applications.

– Aerospace Engineering:These sensors are employed in aircraft and spacecraft to measure airflow over wings and other surfaces, aiding in aerodynamic design and performance optimization.

The advantages of using Karman vortex air flow sensors include their ability to provide accurate and reliable measurements, their non-intrusive nature (allowing for installation without disrupting the flow), and their relatively low cost. However, these sensors may be susceptible to certain environmental conditions, such as extreme temperatures or high levels of vibration, which can affect their performance.

Additionally, they may require regular calibration to maintain accuracy over time.

Design and Construction of Karman Vortex Air Flow Sensors

Karman vortex air flow sensors are meticulously engineered devices, incorporating an array of components and materials to achieve optimal performance. Understanding their design and construction is crucial for comprehending their operation and maximizing their accuracy.

The fundamental components of a Karman vortex air flow sensor include a bluff body, typically a cylinder or airfoil, placed perpendicular to the airflow. As the fluid flows past the bluff body, vortices are shed alternately from either side, creating a periodic pattern downstream.

The frequency of vortex shedding is directly proportional to the fluid velocity, forming the basis for flow measurement.

Materials, Karman vortex air flow sensor

The materials used in the construction of Karman vortex air flow sensors significantly influence their performance and durability. The bluff body is often made of lightweight and durable materials such as aluminum, stainless steel, or composites, ensuring structural integrity while minimizing flow disturbances.

The sensor housing, which protects the internal components, is typically constructed from materials like plastic or metal, providing both protection and environmental resistance. The choice of materials depends on factors such as the operating environment, temperature range, and chemical compatibility.

Accuracy and Performance

The accuracy and performance of Karman vortex air flow sensors are influenced by several factors, including:

- Bluff body shape and size:The shape and dimensions of the bluff body determine the frequency of vortex shedding and, consequently, the sensitivity of the sensor.

- Flow velocity range:The sensor’s operating range is limited by the minimum and maximum flow velocities at which vortex shedding occurs.

- Flow profile:The uniformity of the flow profile is crucial, as disturbances or turbulence can affect vortex shedding and measurement accuracy.

- Temperature and pressure:Changes in temperature and pressure can alter the fluid properties and, thus, the vortex shedding frequency.

By carefully considering these factors and optimizing the design and construction, Karman vortex air flow sensors can achieve high levels of accuracy and reliability in various flow measurement applications.

Signal Processing and Analysis

The signals generated by Karman vortex air flow sensors are processed and analyzed to extract flow rate information. Various techniques are employed, including:

- Frequency analysis:The frequency of the vortex shedding is directly proportional to the flow velocity. By measuring the frequency, the flow rate can be determined.

- Phase analysis:The phase difference between the signals from two sensors placed in the flow can be used to determine the flow direction.

Algorithms and Methods

Specific algorithms and methods used for data interpretation and flow rate calculation include:

- Fast Fourier Transform (FFT):FFT is a mathematical algorithm used to convert a time-domain signal into a frequency-domain signal. It is commonly used to analyze the frequency content of the sensor signals.

- Autocorrelation:Autocorrelation is a statistical technique used to measure the similarity between a signal and a delayed version of itself. It can be used to determine the frequency of the vortex shedding.

- Cross-correlation:Cross-correlation is a statistical technique used to measure the similarity between two signals. It can be used to determine the phase difference between the signals from two sensors.

Calibration and Maintenance of Karman Vortex Air Flow Sensors

Karman vortex air flow sensors require periodic calibration and maintenance to ensure accuracy and optimal performance. Calibration involves comparing the sensor’s output to a known reference flow rate and adjusting the sensor’s parameters to minimize any deviations.

Calibration Procedures

Calibration of Karman vortex air flow sensors typically involves the following steps:

- Connect the sensor to a reference flow rate generator, such as a calibrated wind tunnel or flow bench.

- Measure the sensor’s output voltage or frequency at various flow rates within the sensor’s operating range.

- Compare the measured output to the known reference flow rates.

- Adjust the sensor’s calibration parameters, such as the gain or offset, to minimize the error between the measured output and the reference flow rates.

Maintenance Guidelines

Regular maintenance of Karman vortex air flow sensors is crucial to ensure their continued accuracy and reliability. The following guidelines are recommended:

- Visual Inspection:Periodically inspect the sensor for any physical damage, such as dents or cracks, that could affect its performance.

- Cleaning:Clean the sensor’s sensing element and housing to remove any dirt or debris that could interfere with the vortex shedding process.

- Re-calibration:Re-calibrate the sensor at regular intervals, typically once or twice a year, to ensure its accuracy over time.

- Troubleshooting:If the sensor’s output is not within the expected range or if it is not responding as expected, troubleshoot the system by checking the electrical connections, the flow path, and the sensor’s parameters.

Comparison with Other Air Flow Sensing Technologies

Karman vortex air flow sensors offer unique advantages and disadvantages compared to other commonly used air flow sensing technologies. Understanding these differences is crucial for selecting the most suitable technology for specific applications.

Various air flow sensing technologies exist, each with its own strengths and weaknesses. Some of the most commonly used alternatives to Karman vortex air flow sensors include:

- Hot-wire anemometers

- Turbine flow meters

- Ultrasonic flow meters

- Pitot tubes

The choice of technology depends on factors such as accuracy, sensitivity, cost, size, and the specific application requirements.

Hot-wire Anemometers

Hot-wire anemometers measure air flow by detecting the cooling effect of the air on a heated wire. They are relatively inexpensive and easy to use, but they can be sensitive to contamination and have a limited flow range.

Turbine Flow Meters

Turbine flow meters measure air flow by using a rotating turbine to generate a signal. They are accurate and reliable, but they can be expensive and require regular maintenance.

Ultrasonic Flow Meters

Ultrasonic flow meters measure air flow by using ultrasonic waves to determine the velocity of the air. They are non-invasive and can be used in a wide range of applications, but they can be expensive and sensitive to noise.

Pitot Tubes

Pitot tubes measure air flow by measuring the pressure difference between a stagnation point and a static pressure point. They are simple and inexpensive, but they can be inaccurate at low flow rates and are sensitive to misalignment.

A Karman vortex air flow sensor is a device that measures the flow rate of air or gas. It is based on the principle of vortex shedding, which occurs when a fluid flows past a bluff body. The frequency of vortex shedding is proportional to the flow rate, and this can be used to measure the flow rate.

For more information on free fall tower gizmo answers, visit here . Karman vortex air flow sensors are used in a variety of applications, including automotive, aerospace, and industrial.

Future Developments and Trends

Karman vortex air flow sensors continue to evolve, with ongoing research and advancements shaping their future. These sensors are poised to play an increasingly significant role in various industries.

Potential Future Applications

Future applications of Karman vortex air flow sensors include:

- Enhanced vehicle performance:Integration into engine management systems for real-time flow monitoring, optimizing fuel efficiency and reducing emissions.

- Advanced medical devices:Monitoring respiratory airflow in ventilators and CPAP machines, providing accurate and reliable measurements for patient care.

- Smart building automation:Measuring air flow in HVAC systems, enabling efficient temperature control and energy conservation.

Research Directions

Ongoing research focuses on:

- Improved sensor design:Optimizing sensor geometry and materials to enhance sensitivity, accuracy, and durability.

- Advanced signal processing algorithms:Developing sophisticated algorithms for noise reduction and flow rate estimation, increasing data reliability.

li> Wireless communication integration:Incorporating wireless capabilities for remote monitoring and data transmission.

Q&A

What is the principle behind Karman vortex air flow sensors?

Karman vortex air flow sensors rely on the formation of Karman vortices, which are swirling eddies that form behind a bluff body placed in a fluid stream. The frequency of these vortices is directly proportional to the fluid velocity, allowing for accurate flow rate measurement.

What are the advantages of using Karman vortex air flow sensors?

Karman vortex air flow sensors offer several advantages, including high accuracy, wide flow range, low pressure drop, and insensitivity to flow disturbances.

What are some common applications of Karman vortex air flow sensors?

Karman vortex air flow sensors find applications in various industries, such as automotive engineering, HVAC systems, environmental monitoring, and industrial process control.